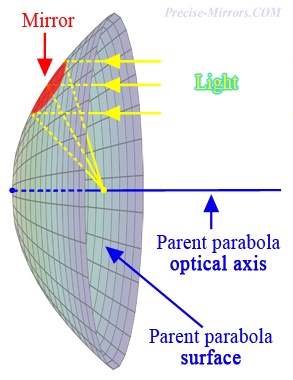

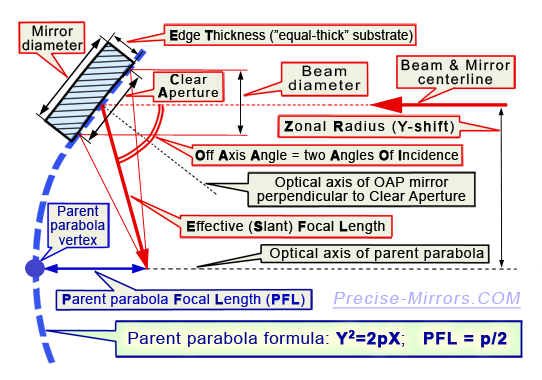

Off-axis parabolic (often also written OAP - Off Axis Parabolic) mirrors this is part of the surface of a paraboloid of revolution (see the figure below on the left, the mirror is shown in red, the yellow the color is radiation, blue is the optical axis of the parabola). The figure below on the right shows the names of the parameters, used in the description of off-axis parabolic mirrors. High radiation resistance (You can also say high damage threshold or in English they often write LIDT - Laser Induced Damage Threshold) - this is the ability of the mirror reflect high-intensity radiation, more about this below.

The main property of a parabolide: the ray emerging from its focus after reflection from its surface will move parallel to the optical axis of the paraboloid. Thus, OAP mirrors make it possible to obtain a collimated beam from a point source that is NOT located on the optical axis of the reflecting mirror itself (whereas for an axial parabola the source is always located on the optical axis of the mirror itself). OAP operation scheme is not axisymmetric (whereas the axial parabola has an axisymmetric scheme).

Typically, off-axis parabolic mirrors are used in optical designs where the angle of incidence does not exceed 45 degrees

(moreover, if we are talking about precise and ultra-precise parabolic mirrors, the angle of incidence rarely exceeds 10-20 degrees).

In these cases, off-axis parabolic mirrors are most often used for two purposes.

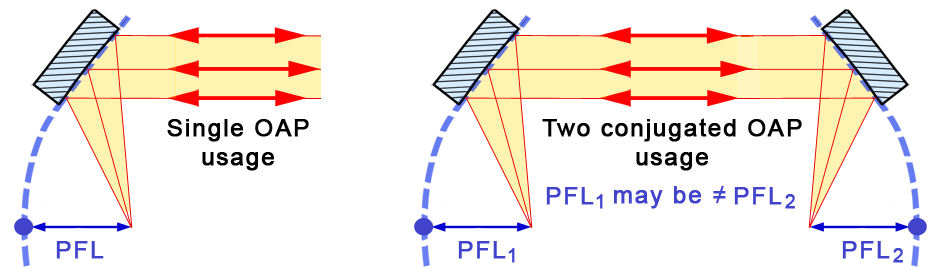

The first task is the work of one mirror, which either focuses the collimated beam to a point, or vice versa

creates a collimated beam from radiation diverging from a point source (see the left side of the figure below).

The second task is the work of two conjugated mirrors, with the help of which a collimated

the beam, and then it will be focused back to a point (see the right side of the figure below).

Also, off-axis parabolic mirrors are sometimes used to build telescopes, but still for these tasks more often used axial parabolic mirrors with a hole in the center. There is also another non-standard, but very promising method of using OAP mirrors in "grazing schemes" (this is when the angle of incidence is very large, for example 70-89 degrees). Such large angles of incidence allow the use of such off-axis parabolic mirrors for reflecting radiation with short wavelengths (less than 50-100 nm and up to a few nm), which gives the ability for such mirrors to operate in the deep UV part of the spectrum (for certain coatings - even with high LIDT).

With an increase in the radiation power that the mirror reflects, at some point at a certain threshold value power, the reflective coating is destroyed (or, for example, the substrate surface of the mirror itself, if there is no coating). This value is called the "damage threshold" of the mirror (in English they usually write L. I. D. T.). It can be indicated in units of power per unit area, but for pulsed radiation it is customary to indicate it as units of energy per surface area unit for a pulse with certain duration. For example, if the breakdown threshold for a mirror is specified as 10 J/cm2 (for a 10 ns pulse), this means that every square centimeter of this mirror can reflect a pulse with a duration of 10 ns and an energy of 10 J.

The exact value of the damage threshold (L.I.D.T.) depends on:

--- the mirror itself (type of reflective coating, quality of coating and manufacturing of the mirror) and

--- radiation parameters (pulse energy, their duration and repetition rate, spectral range, size of the irradiated

areas, duration of irradiation and some other factors.

Mirrors with dielectric coating have the highest damage threshold (high LIDT),

average typical values for dielectric coatings are:

--- for pulsed radiation 10-20 J/cm2 (λ=1064 nm, 10 ns, 10 Hz, irradiation 1 mm2) and

--- for continuous radiation approximately 3-20 kW/cm2 (λ=1064 nm, irradiation 1 mm2).

Mirrors with a metal coating (but not the metal backing of the mirror itself) have a noticeably lower

damage threshold (lower LIDT), average typical values for metal coatings are:

--- for pulsed radiation 0.5-2 J/cm2 (λ=1064 nm, 10 ns, 10 Hz, irradiation 1 mm2) and

--- for continuous radiation approximately 0.5-1 kW/cm2 (λ=1064 nm, irradiation 1 mm2).

Using various methods, it is possible to obtain higher damage threshold values (better LIDT), e.g.

for dielectric mirrors:

--- for continuous radiation it is possible to achieve 50-150 kW/cm2 (λ=1064 nm) and

--- for pulsed radiation it is possible to achieve 70-90 J/cm2 (pulses 10 ns, λ=1064 nm).

IMPORTANT! If you change the radiation wavelength, pulse duration, or size of the irradiated area the value of the damage threshold changes strongly and nonlinearly.. Moreover, with a sufficiently large change even one of the radiation parameters (for example, pulse duration), a model of the interaction of radiation with the coating of the mirror will fundamentally change, which can change the value of the damage threshold by several orders of magnitude in one direction or another. Therefore, it is very important that a specialist assess the damage threshold for your task.

| Mirror minimal and maximal sizes: | from 40 mm to 1200 mm | |

| Mirror substrate material: | Astrositall, by request: Zerodur, UV FS, Si and other. | |

| Coatings: | Metallic (Ag, Au, Al) and special EUV|XUV. | |

| Manufacture accuracy (RMS, λ=633 nm) | Base | Maximal |

| surface shapes, aspherical mirrors | up to λ/40 | up to λ/150 |

| Radiuses manufacture accuracy | up to ±0.1% | up to ±0.05% |

| Surface microroughness, RMS | 0.3 nm | 0.15 нм |

| Cosmetic quality (per square inch) | 60/40 scratch/dig | 10/5 scratch/dig |

The main advantage of off-axis parabolic mirrors is that they virtually have no aberrations at all (at least from a practical

point of view) Thus, with sufficiently good accuracy in manufacturing the shape of the reflective surface, the result will be determined

by diffraction limitations optical design.

The main disadvantage of off-axis parabolic mirrors is that when we are talking about precision and ultra-precision mirrors

(λ/30-λ/150 RMS), then their production is extremely labor-intensive and requires high costs (especially for mirrors with

large asphericity), and accordingly the cost and timing supplies of such mirrors are noticeably larger than for conventional spherical

optics (even if they are also very accurate).

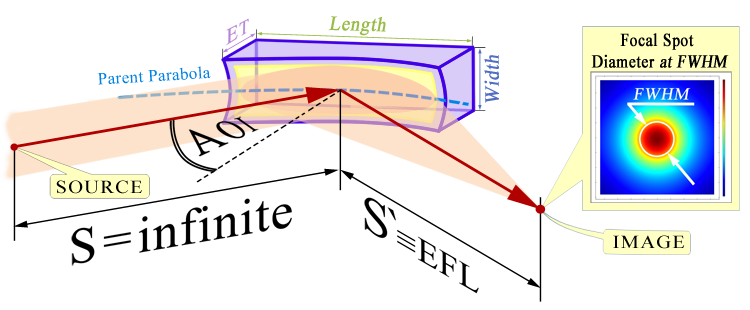

Typically, it is very important for the customer how small a spot in the image plane can be formed by the mirror (see figure below). Even if the task is to obtain a collimated beam or construct an image, the value of the minimum focused spot size allows You to evaluate the quality (for example, divergence) of the resulting collimated beam or image (resolution).

The size of the spot in the image plane can be influenced by many different factors, but from actual practice these are mainly spherical aberrations, manufacturing precision of the mirror surface shape, and sometimes diffraction limitations at the operating wavelength. Also, the accuracy of the adjustment is often extremely important, since sometimes for example, an error in mirror position of just a few microns can increase the diameter of the focused spot several times.

The general principle is that the closer the size of focused spot

to the diffraction limit, the more expensive such a mirror is.

It depends on your task and the funds allocated for the purchase. The most competent and correct way would be to fill out our special "request form". It is also advisable to attach to the request form a description of your optical design (at least in words) in which the mirror will operate (especially if we are talking about the operation of two requested mirrors in a paired pair) and send all this to our e-mail quote@precise-mirrors.ru. Next, our specialists will select several suitable options for you (see example of a typical quote for single mirrors or for two conjugate mirrors ).

You can also send a detailed exact specification of the mirror you need with drawings, a description of the type of surface shape, calculated constants, with all tolerances, etc. But even in this case, it is better to add at least minimal information on your optical design, We may be able to offer some improvements to the specification of your mirror. In this case, the customer does not bear any additional expenses.

You also don’t have to fill out "request form" , and do not send a detailed exact specification of the mirror you need, but instead send a description of Your task (mirror) in any form to the same email address quote@precise-mirrors.ru. But in this case, such a request may take much longer to process.